We Opened Daily 8.00 am- 8.00 pm

We Opened Daily 8.00 am- 8.00 pm  We Opened Daily 8.00 am- 8.00 pm

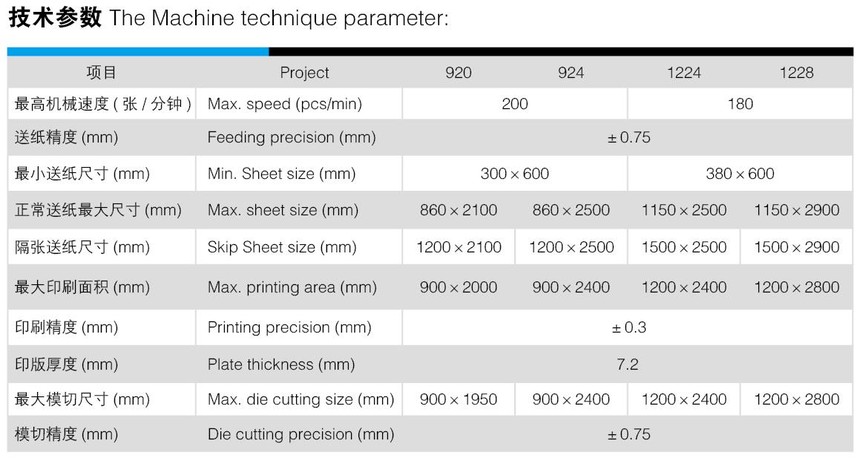

We Opened Daily 8.00 am- 8.00 pm ◆ High precision: ±0.3mm registration accuracy, from the servo drive, pressure free paper feeding system and the whole vacuum adsorption transfer.

◆ High network cable: 130Lpi printing network cable, from the closed scraper with ceramic roller and precision pressure regulation system.

◆ High efficiency: "Paper feeding - dust removal - printing - infrared drying - glazing - infrared (ultraviolet) drying - die cutting - waste cleaning - stacking" completed in one time

◆ High precision: ±0.3mm registration accuracy, from the servo drive, pressure free paper feeding system and the whole vacuum adsorption transfer.

◆ High network cable: 130Lpi printing network cable, from the closed scraper with ceramic mesh roller and fine. Tight pressure regulation system.

◆ High efficiency: "paper feed - dust removal - printing - infrared drying - glazing - infrared (ultraviolet) drying - die cutting - waste cleaning - stacking" a complete production process, between 100 to 150 sheets/minute production speed.

◆ High quality: Using CNC intelligent control system and Germany Bosch Rexroth cooperation, through the network, to achieve remote maintenance, to ensure long-term stable operation of equipment.

◆ Low consumption: Excellent detail design and on-line production mode, which can save more production materials and labor costs.

◆ Servo motor independent drive, no gear backlash wear, long life, high precision.

◆ Vacuum adsorption leading edge paper feed, frequency conversion control air volume, paper feed stability.

◆ Extended paper feeding system, according to the length of the board, determine the size of the paper feeding stroke, improve the accuracy of the paper feeding.

◆ Non-pressure feeding system, avoid the cardboard transfer process is destroyed, to ensure the compressive strength of the original cardboard.

◆ The whole machine automatic zeroing system, store common orders, quick order change, easy operation.

◆ Widened dust removal device, remove electrostatic brush, can remove the paper dust on the surface of cardboard, improve the printing quality.

◆ Left and right baffles and back plates are controlled by computer, precision steering mechanism, stable displacement, with side shot function.

◆ Full vacuum adsorption, with ceramic paper feed wheel transfer system.

◆ Frequency conversion to adjust the adsorption wind, can also automatically adjust the switch of the damper according to the length of the cardboard.

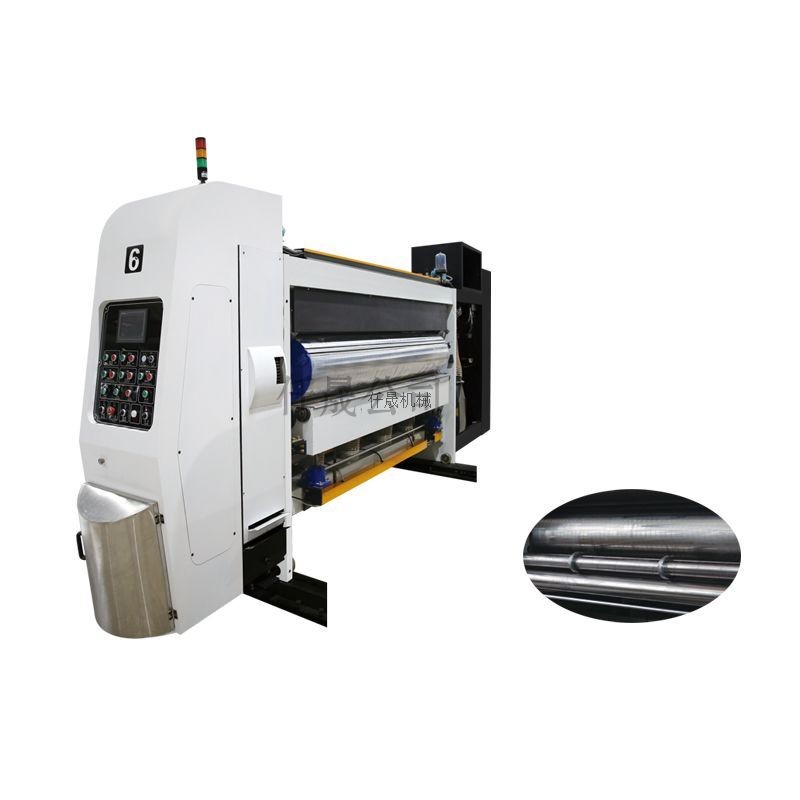

◆ Closed scraper with ceramic mesh roller, to achieve high dot precision. Tight printing, uniform force of scraper, simple adjustment and maintenance.

◆ Pneumatic double diaphragm pump, fast cleaning function, ink supply, stable circulation, simple operation and maintenance.

◆ Quick change of rubber roller, mesh roller device, equipped with quick change bracket.

◆ Tilt correction roller, the tilt error can be quickly corrected on the plate roller, and the plate is convenient and fast.

◆ Erasing memory, automatic reset system.

◆ Infrared drying method to avoid ink printing or glazing effect.

◆ Infrared drying box lifting pneumatic control system, drying box can be lifted quickly.

◆ The drying range can be selected according to the width of the cardboard to save energy.

◆ The same full vacuum adsorption with ceramic paper feed wheel transfer system to ensure the stability of cardboard transfer.

◆ Frequency conversion adjustment of adsorption wind, but also according to the length of the cardboard electric adjustment of the bellows throttle.

◆ UV drying system can be selected to dry UV varnish on the surface of printed matter.

◆ Independent servo drive to avoid printing effect due to die cutting impact.

◆ Equipped with imported quick-change polyurethane rubber pad, easy to replace, with one-way clutch as linear speed compensation function, to ensure that the rubber pad wear out of the die-cut cardboard is completely consistent.

◆ In the work of die cutting rubber pad roller mechanical spiral automatic transverse movement (±20mm), so that the cut marks do not repeat, extend the service life of the rubber pad.

◆ The gap between the rubber cushion roll and the die cutting roll is controlled by pneumatic control. The rubber cushion roll drops to the working position when the paper is fed normally, and the rubber cushion roll rises automatically when the paper is stopped.

◆ Rubber pad correction mechanism, increase the use of rubber pad, reduce consumption.

◆ The bottom of the die cutting is equipped with a waste paper conveying device, which transfers the paper scraps after the die cutting to the outside of the equipment for easy cleaning.

◆ The stackable height of cardboard is 1600mm.

◆ Bed lift by strong. Force chain drive. Lift motor with brake function to maintain a fixed position, will not slide.

◆ The bed is automatically raised and lowered with the stacking of cardboard. When the cardboard is stacked to a predetermined height, the pneumatic paper lifting mechanism automatically opens, catches the cardboard, and the paper is full of alarm. Full protection device, forced bed will not suddenly slide, to ensure the safety of operators.

◆ Flat crepe climbing conveyor belt, cardboard will not slide.

◆ Stacker width is 2200mm, 3200mm.