We Opened Daily 8.00 am- 8.00 pm

We Opened Daily 8.00 am- 8.00 pm  We Opened Daily 8.00 am- 8.00 pm

We Opened Daily 8.00 am- 8.00 pm

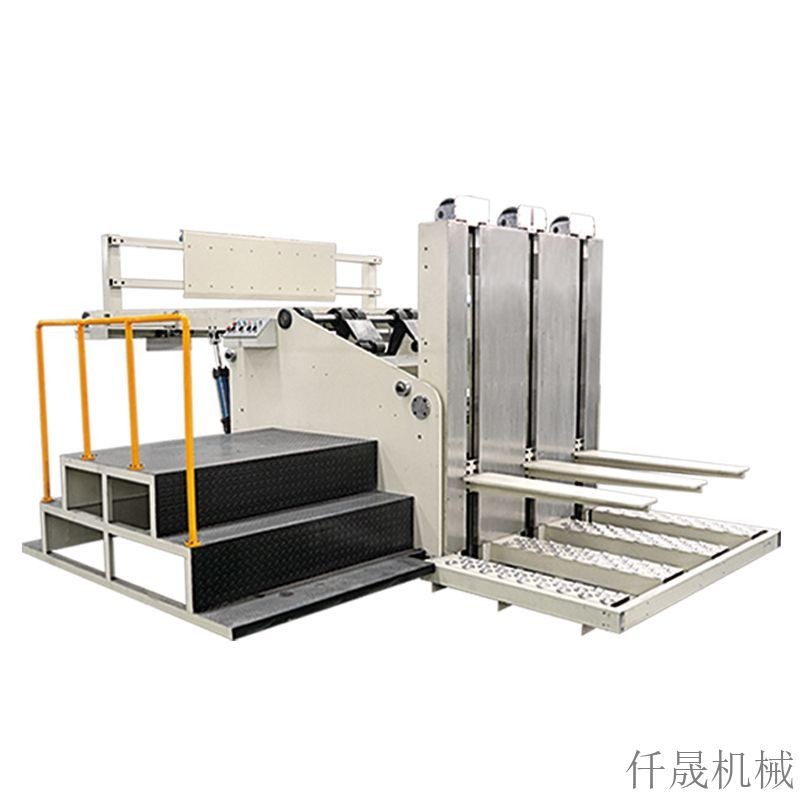

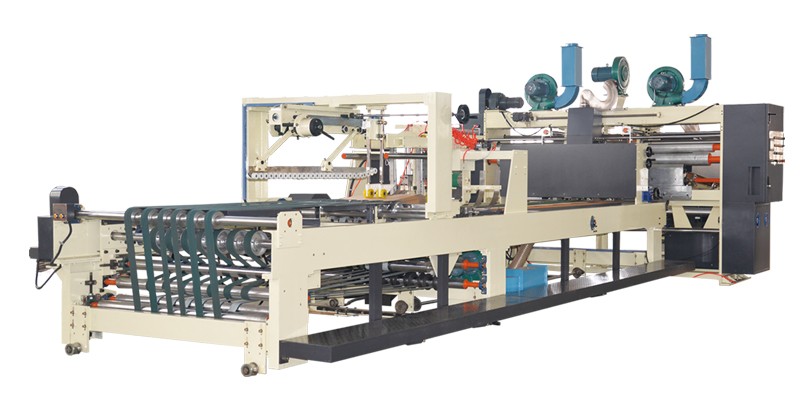

◆ Both side positioning baffle, can be adjusted according to different size of the cardboard, specification with electric adjustment.

◆ Operation control is simple and convenient.

◆ Supporting paperboard roller way can connect cardboard logistics delivery system.

◆ Horizontal conveyor belt automatic control with hydraulic motor drive.

◆ Traveling mechanism can connect with printing machine synchronously.

◆ Automatic control paperboard transport with PLC.

◆ Design security accord with the European CE safety standards and strive to humanized operation.

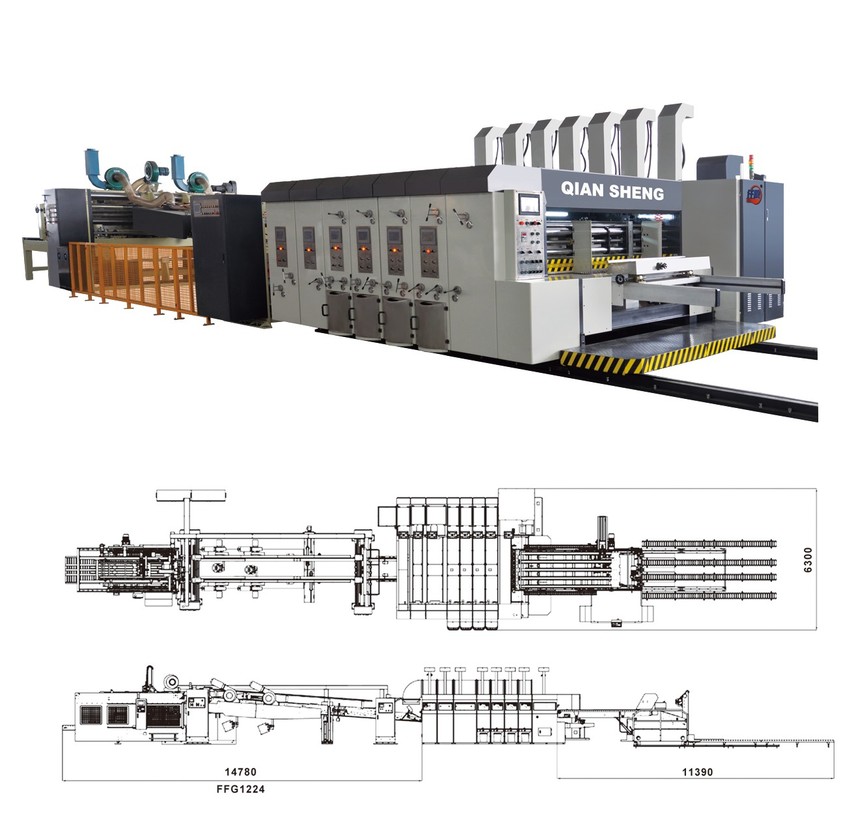

◆ Adopt America SUN company lead edge feeding paper technology with high precision.

◆ Adopt America SUN technology single doctor blade, the printing is more clear and perfect.

◆ Vacuum transfer paperboard system, wind power balance design makes running accuracy higher, feeder system can be flexible matching roller feeding and hot air drying system function, or achieve roller feeding and vacuum transfer double function, saving energy and reducing consumption.

Drying system,which has two kinds of infrared and ultraviolet ray, can respectively drying water-based ink, light oil and UV light oil. Temperature control system to ensure the safety of production. According to the board width automatically, adjust scope of dry, to save energy.

◆ Double system of touch screen and electric button control ,can completed at the box

phase , the axis moves.

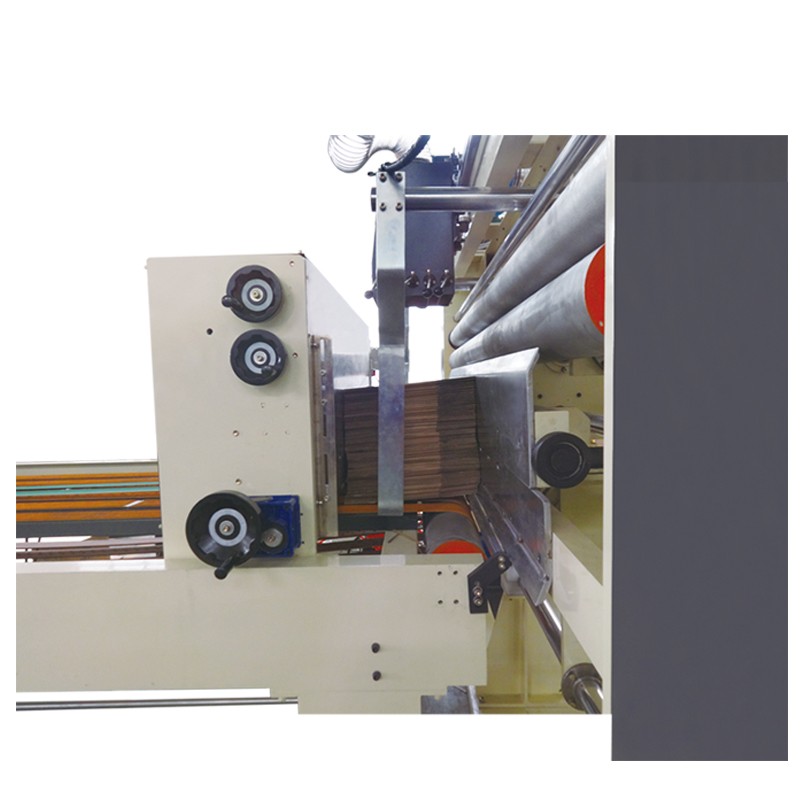

◆ Configuration pressure quick adjust mechanism ,and can self-locking, ensure the plate and roller long-term precision, slow down damage to cardboard when groove.

◆ Up-groove wheel parcel the quality polyurethane ,avoid cardboard hardness undermine.

◆ Settings synchronous manner unified action by the axis moves , let up and down groove wheel ,up and down slot knife plate, oriented wheel adjust synchronous; Automatic wear-resistant mechanism,ensure long-term correct when moves and raise durability.

◆ Groove wheel and roller , slot wheel and roller use quality alloy steel products, surface grinding and hard chrome plating: to move their respective balance.

◆ Slotter knife use quality alloy steel products, the width is 7mm.

◆ Die-cutting anvil roller adopt single servo more independent drive, realizes speed difference compensation between rubber cushion and template manufacturing error compensation

◆ Die-cutting roller automatically eliminate the adjusting mechanism gap and die cutting vibration, improve the service life of the equipment.

Glue system with constant temperature

CNC control sheet cleaning system

Precision deflection wheel system to ensure feeding register vacuum transportation when folding.

High rigidity beam Linear guideway Lateral moving system.

prolong the time of cardboard correction, stable the gluing

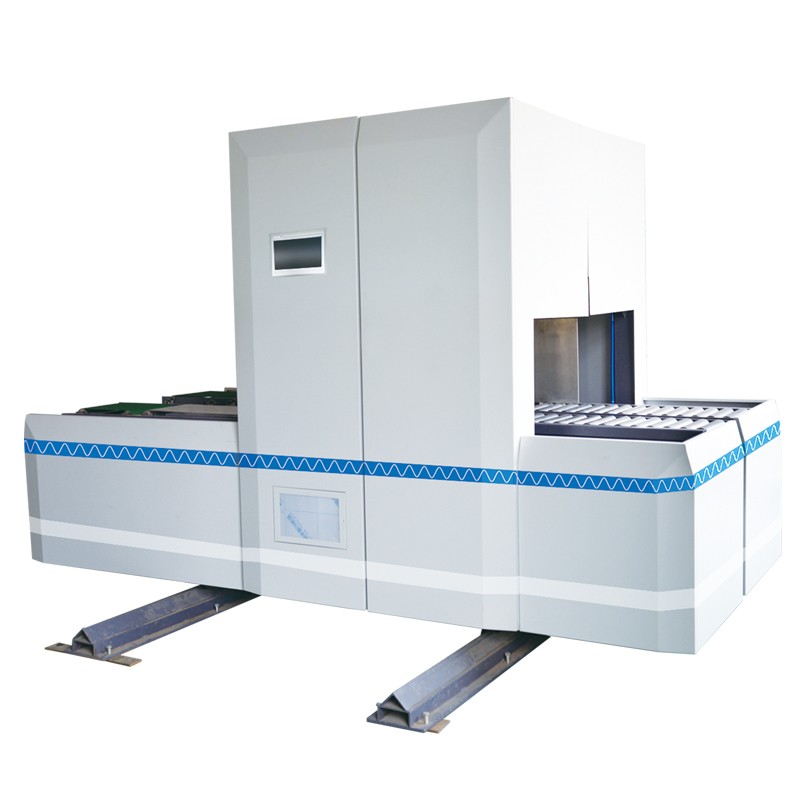

Suitable use: the binding of large objects such as cartons, pit paper, cardboard, newspapers, books

and periodicals, and the binding of clothing are widely controlled by machinery (or electronics), with stable working performance, solid and durable body, and simple maintenance.