We Opened Daily 8.00 am- 8.00 pm

We Opened Daily 8.00 am- 8.00 pm  We Opened Daily 8.00 am- 8.00 pm

We Opened Daily 8.00 am- 8.00 pm

We are a professional manufacturer of complete sets of cardboard box machinery and equipment, integrating research and development, production, sales, service, and high-tech management system.

Continuously optimizing and improving, innovating, and wholeheartedly providing better professional products and services for the vast number of cardboard box production enterprises.

Our company will establish information files for customers in order to provide them with faster, more professional, and high-quality after-sales service.

Hebei Dongguang Desheng Carton Machinery Co., Ltd. is strategically located in the heart of the Bohai Economic Circle, north of Beijing and Tianjin, and south of Jinan. This prime location offers convenient land and waterway transportation options. Our company specializes in the production of carton packaging machines and printing machinery. With a focus on independent research and development, we continuously enhance our high-tech capabilities to address existing inefficiencies in both international and domestic markets. Our goal is to advance towards high-speed, efficient, durable, energy-saving, and safe automation machinery.

We prioritize talent acquisition and boast a robust technical team. Utilizing advanced design software, sophisticated production equipment, and state-of-the-art detection methods, we enforce strict quality management systems. Our skilled production team ensures top-notch product quality and performance. By maintaining these high standards, we lay a solid foundation for continuous improvement and customer satisfaction.

High Precision: +0.3mm accuracy is derived from servo drive, No pressure feeding system and vacuum absorption transmission.

High Precision: +0.3mm accuracy is derived from servo drive, No pressure feeding system and vacuum absorption transmission.

High definiton: 130Lpi Printing Line, Originated from Closed doctor blade with Ceramic anilox Roller and Precision Pressure Regulating Systemn.

High definiton: 130Lpi Printing Line, Originated from Closed doctor blade with Ceramic anilox Roller and Precision Pressure Regulating Systemn.

High efficiency: Paper feeding, dust removal, printing, infrared drying, polishing,infrared(ultraviolet)drying, die cutting and stacking.complete the production process at one time. The production speed is between 100 and 150 pcs per minute.

High efficiency: Paper feeding, dust removal, printing, infrared drying, polishing,infrared(ultraviolet)drying, die cutting and stacking.complete the production process at one time. The production speed is between 100 and 150 pcs per minute.

High Quality: CNC Intelligent Control System is used to cooperate with Germany Bosch Rexroth to achieve long-distance maintenance through network and ensure long-term stable operation of equipment.

High Quality: CNC Intelligent Control System is used to cooperate with Germany Bosch Rexroth to achieve long-distance maintenance through network and ensure long-term stable operation of equipment.

Low Consumption: Excellent detail design and on-line production can save more production materials and labor costs.

Low Consumption: Excellent detail design and on-line production can save more production materials and labor costs.

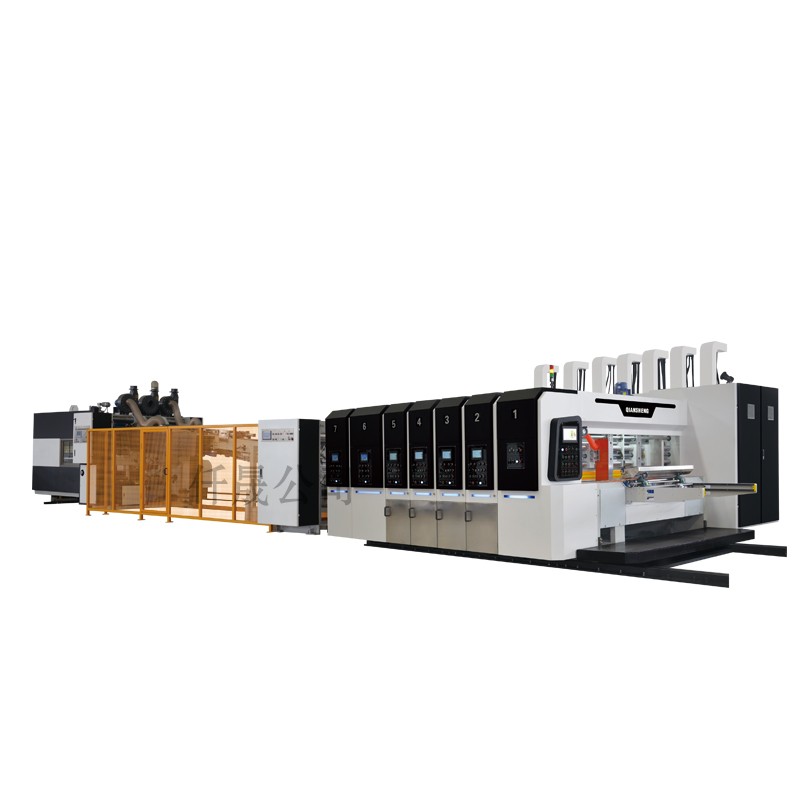

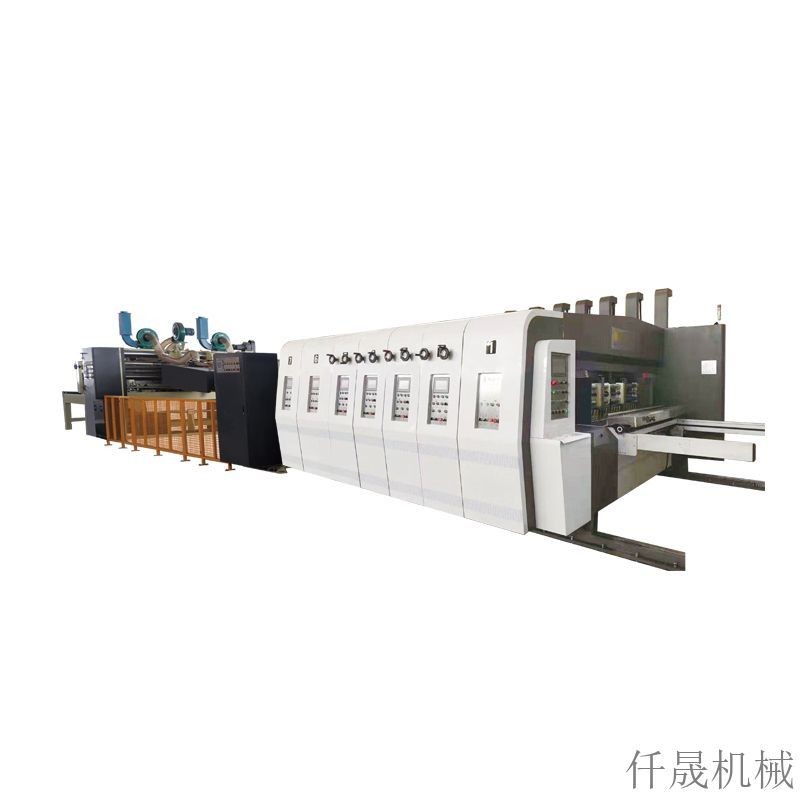

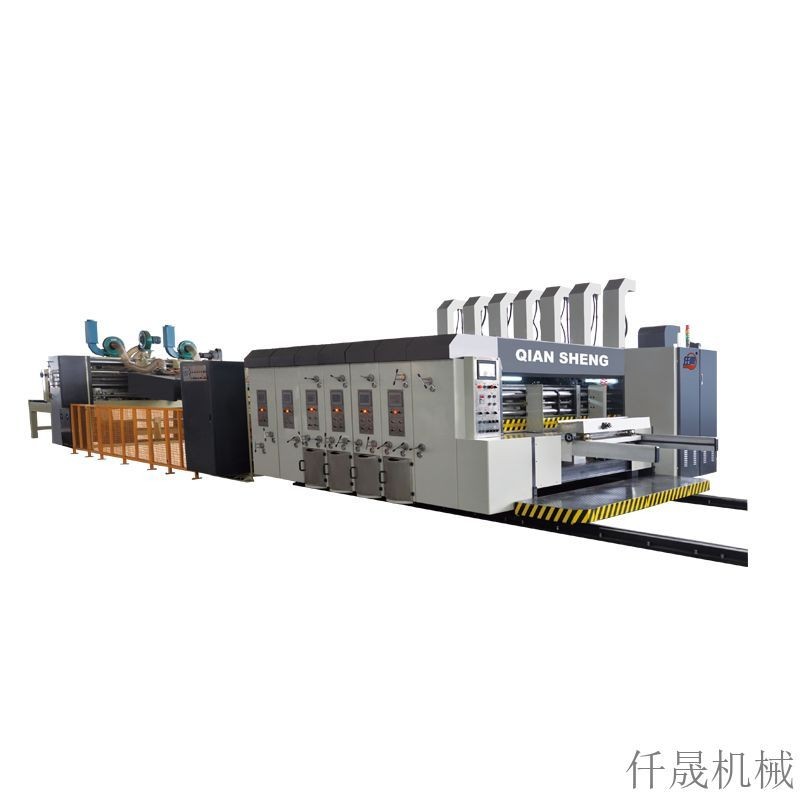

DS-GYKM fully automatic high-speed ink printing, slotting, die-cutting, adhesive box nailing, packaging and integrated linkage line and other products.

DS-GQYKM-A has multiple products including full process vacuum adsorption, high-definition printing, drying, polishing, drying, die-cutting machine, etc.

WJ-200-2200 seven layer high-speed corrugated cardboard production line and multiple other products.

Multiple products including intelligent fully automatic adhesive nail machine.

According to the statistics of the European Federation of printing and paper processing machinery manufacturers' associations (eumaprint), due to the impact of the world economic downturn, the sales of printing machinery and equipment in seven countries, including Germany, France, the United States, Italy and Switzerland, decreased by 13.08% in 2002 compared with 2001.

Single sided corrugating machine is facing eliminationSince the development of single-sided machine, due to its low grade, it can not guarantee the quality of cartons, so it is facing elimination.In the early 1990s, the agency issued a quality license for export carton packaging and believed that the single-sided machine could ensure the carton quality, which was still a decision made from reality at that time.

1. Ensure that the aircraft receiver is responsible for supervising the machinery, equipment and crew operators.2. Before operation, the operators shall wear work clothes, work hats and work shoes neatly, fasten the skirt and cuffs, and do not put sundries that are easy to fall out in the pocket, and do not wear watches and various accessories.3. Before starting the machine, add the required lubricating oil (grease) to each oil filling point, lubricating point and oil tank of the machine.

The dynamic maintenance of printing press refers to the maintenance of the machine when the printing press is in a dynamic state. Machine static maintenance is the premise of machine dynamic maintenance. At the same time, the dynamic operation of the machine can in turn detect the level of machine static maintenance. The dynamic maintenance of the machine is very important. The following analyzes the main contents that should be maintained under the dynamic condition of the machine from several aspects.

The static maintenance of printing press refers to the maintenance of the machine under the static state of the machine.1. Establish rules and regulations for machine maintenance. The maintenance of offset press shall be subject to the instructions of the machine. Such as regular oil change, filter cleaning, regular testing of machine accuracy, etc.2. Strengthen the maintenance of important parts. Gears, cams, sprockets, rollers and bearings are important parts of the printing press.

The full-automatic gluing machine is a mechanical device that automatically completes the processes such as paperboard feeding, deviation correction, mark line shaping, gluing, folding, pressurization, alignment, counting and discharge at one time. Its characteristics can reduce the dependence of carton enterprises on a large number of skilled carton gluing workers, save the workplace, and greatly improve the work efficiency and product quality.